Zero Corrosion: The Surface Reinforcement Advantage of GFRP Mesh

Protecting concrete where damage starts first

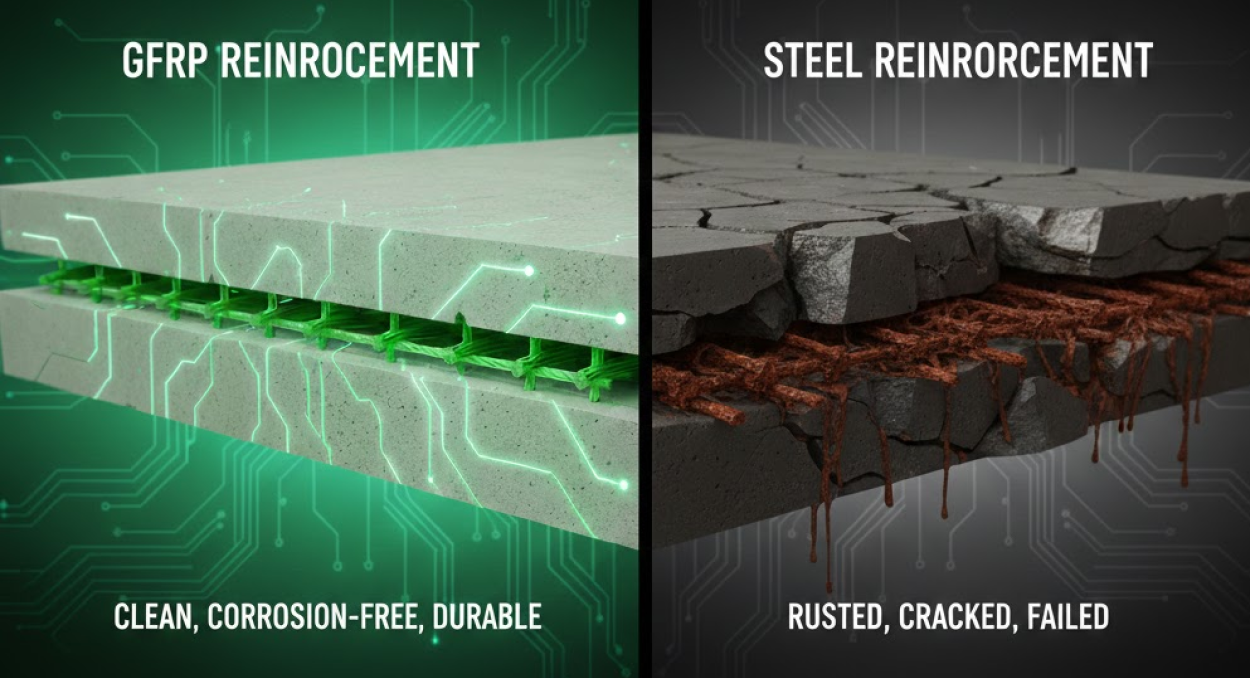

Surface reinforcement is the most vulnerable part of reinforced concrete. In slabs, podium decks, and parking structures, the mesh is positioned closest to moisture and chlorides. That makes steel mesh the first material to corrode — and when it fails, the entire slab begins to deteriorate.

GFRP Mesh (Glass Fiber Reinforced Polymer) eliminates corrosion completely. This prevents the most common causes of surface cracking, spalling, and expensive slab restoration.

Why Zero Corrosion Matters for Mesh

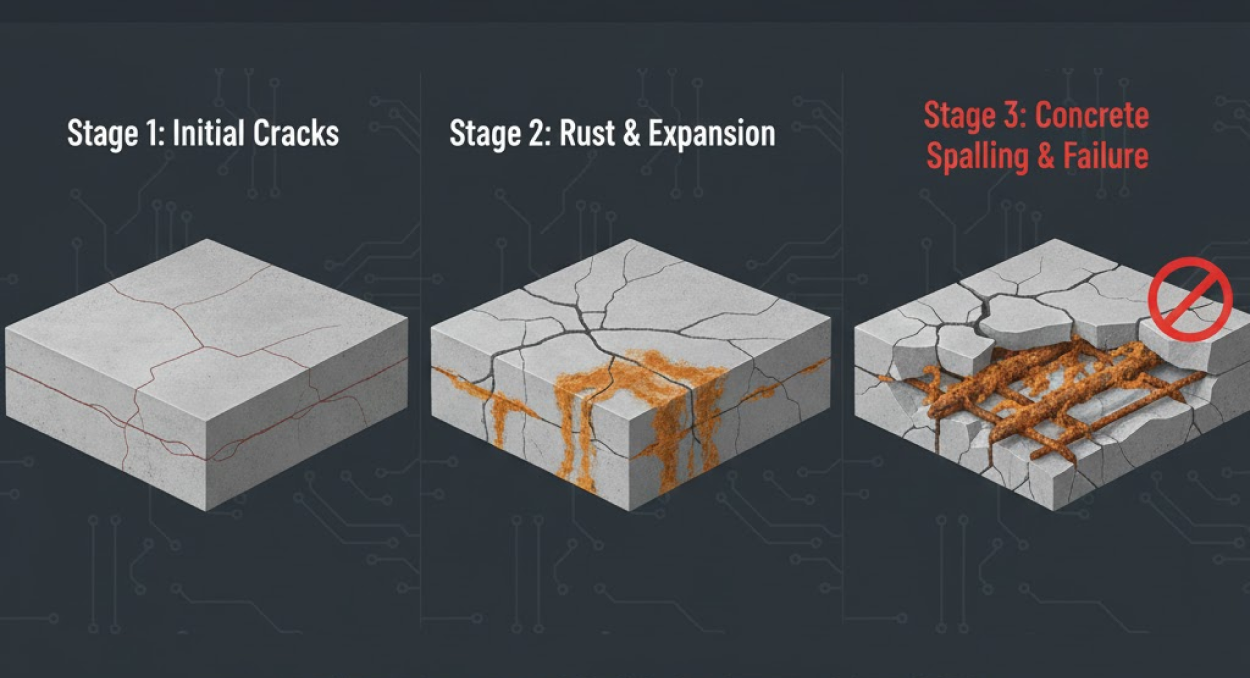

Steel mesh corrosion leads to:

- Rust expansion → spalling and concrete popping

- Loss of bond → cracks widen fast

- Surface deterioration → unsafe and unattractive structures

- Expensive resurfacing and shutdowns

GFRP Mesh = 100% Corrosion-Proof Reinforcement

Key benefits:

- No rust

- No weakening from water or chlorides

- No protective coating needed

- Maintains performance over 75–100+ years

Mesh remains structurally reliable from Day 1 to Year 100 “Zero corrosion means zero surprise repairs.”

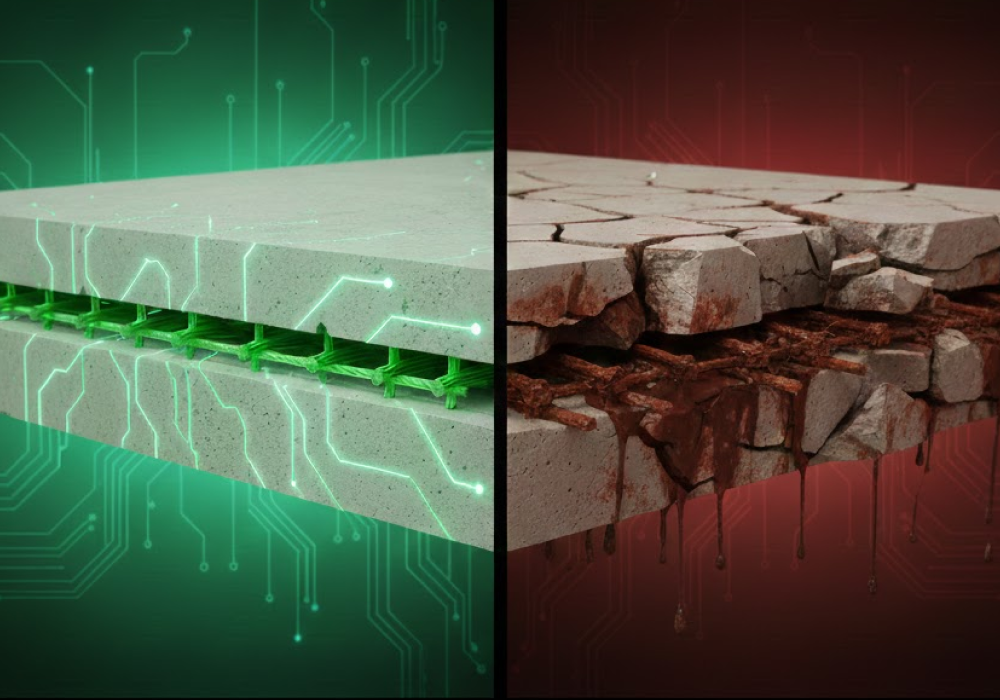

GFRP vs Steel — Corrosion Performance Comparison

Factor

GFRP Mesh

Steel Mesh

Corrosion

None

Inevitable

Crack Spalling

None

Frequent

Surface Durability

High

Low

Application-Based Zero Corrosion Benefits

Here’s how GFRP Mesh improves durability across industries:

1 - Residential & Commercial Slabs

- Mesh near surface → faster corrosion in moisture zones

- GFRP = no basement resurfacing expense

2 - Parking Structures & Podiums

- Water + deicing salt exposure destroys steel quickly

- GFRP preserves concrete surface strength

3 - Marine & Coastal Boardwalks

- Salt spray + tides destroy steel mesh

- GFRP Mesh remains unaffected for decade

4 - ndustrial Floors

- Chemical spills accelerate corrosion

- GFRP prevents surface degradation and operational hazards

5 - Wastewater Plants

- Mesh near the surface is constantly exposed to moisture

- Zero corrosion prevents leaking and contamination

6 - Healthcare Facilities

- No slab cracking → hygiene maintained

- Avoids costly shutdowns for repairs near sensitive equipment

7 - LEED Buildings

- Durability = sustainability

- No demolition waste

- Lower carbon footprint across service life

Real Case Example — Podium Deck Corrosion

GFRP Mesh Scenario:

- No rust

- No spalling

- No disruption or resurfacing

Steel Mesh Scenario:

- Significant spalling after 7–10 years

- Ongoing patch repairs & resurfacing

- Water penetration leads to waterproofing repair cycles

ROI Table — Zero Corrosion Savingsy

Cost Category

GFRP Mesh

Steel Mesh

Surface Cracking Risk

None

High

Maintenance Frequency

Zero

High

Shutdown Disruption

None

Likely

Waterproofing Repair

Avoided

Common

Total Cost Over 75+ Years

Lowest

Very high

Conclusion

Steel mesh is the weakest corrosion point in concrete slabs — the first place where damage begins.

GFRP Mesh delivers:

- Zero rust

- Zero spalling

- Zero maintenance expense

- Zero durability concerns

- Maximum lifecycle performance

Zero corrosion isn’t a luxury — It's the new standard for modern construction. — visit: www.gogbars.com