Stronger for Longer: Why GFRP Mesh Delivers Better Strength in Concrete

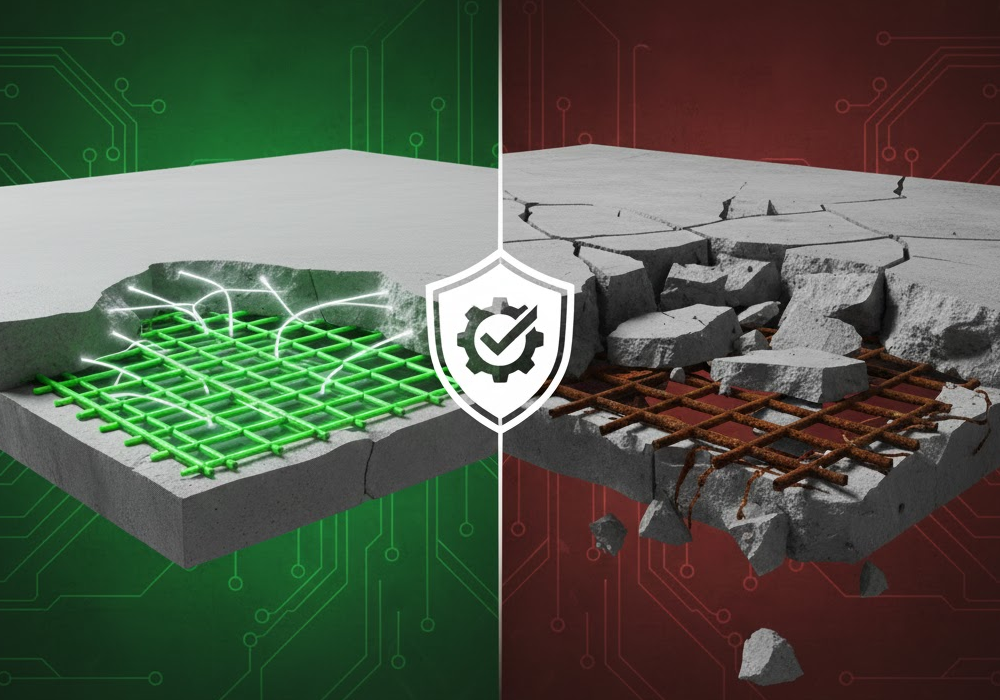

Superior crack control and long-term slab durability

Strength is the foundation of performance in reinforced concrete slabs and decks. Mesh reinforcement plays a vital role in:

- Controlling crack spread

- Distributing loads

- Maintaining long-term durability

However, steel mesh loses strength over time due to corrosion — and that directly weakens concrete performance.

GFRP Mesh (Glass Fiber Reinforced Polymer) provides high tensile strength that never degrades — ensuring crack control and structural reliability for 75–100+ years.

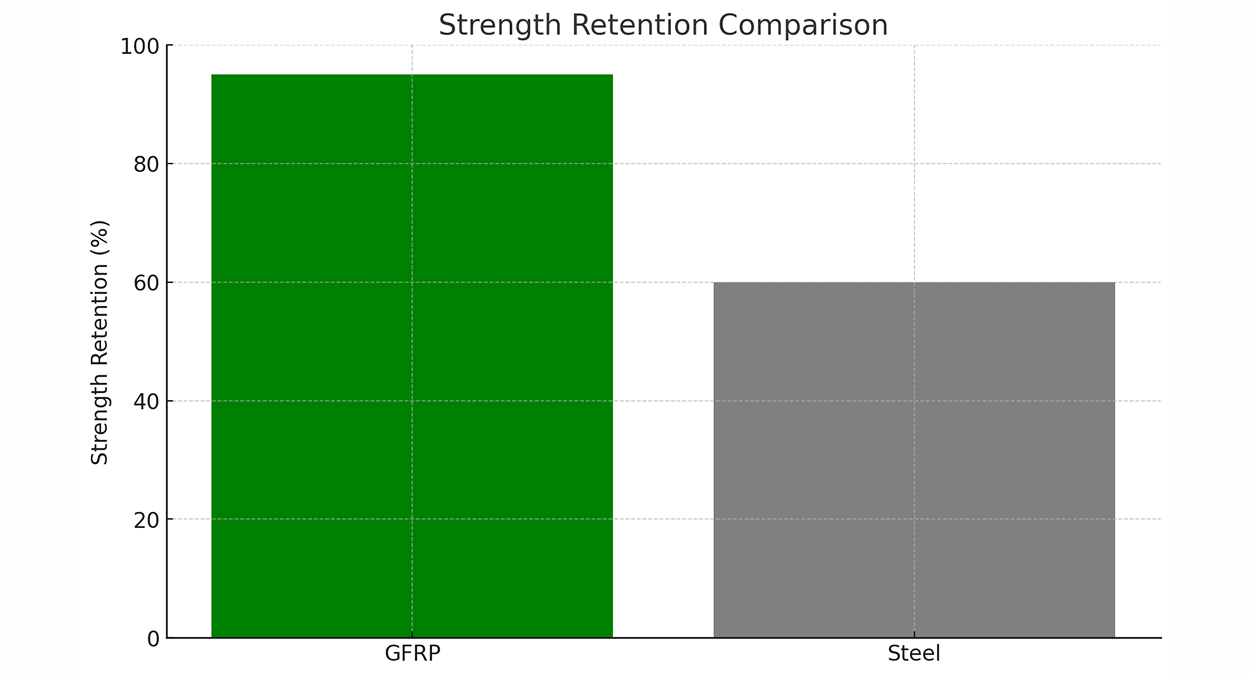

Strength Comparison: GFRP Mesh vs Steel Mesh

Steel mesh begins strong but loses most of its tensile capacity once corrosion sets in.

Strength Factor

GFRP Mesh

Steel Mesh

Initial Tensile Strength

Strong-to-Excellent

Strong

Strength Retention

No change

Weakens with corrosion

Crack Resistance Over Time

Constant

Decreases

Long-Term Durability

Very High

Low

Strength-to-Weight Ratio Advantage

GFRP offers higher performance while being ~4X lighter than steel.

This enables:

- Better crack distribution

- Faster installation

- Safer manual handling

- Strong performance in seismic or vibration environments

Lightweight does not mean weaker — It means more efficient strength in the structure.

Bond + Strength = Better Crack Control

Proper bond enables tensile strength to work. GFRP Mesh is engineered with a textured, sand-coated surface:

- Crack widths remain narrower

- Water and chemicals cannot enter

- Slabs remain in service much longer

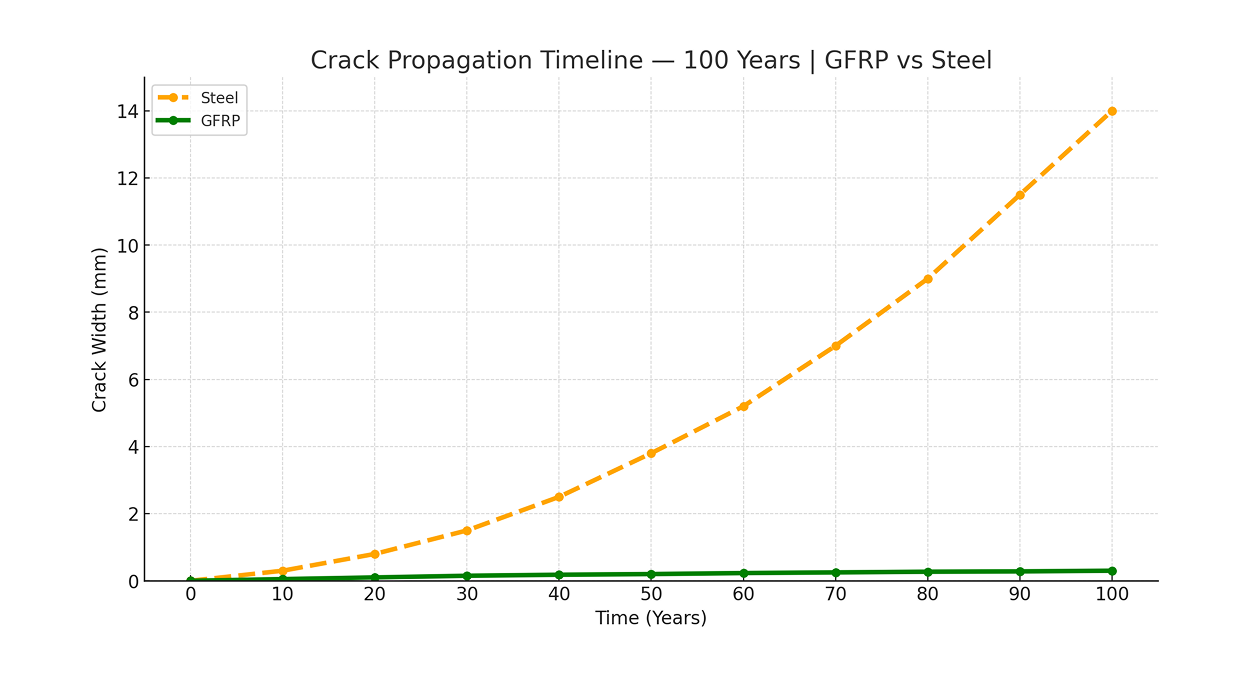

Dynamic Load & Vibration Strength

Especially critical across:

- Parking decks

- Heavy load slabs

- Hospital & lab floors

- Industrial locations with machinery

teel weakens as it corrodes — GFRP remains strong under repeated load cycles

Application-Based Strength Advantages

01 - Residential & Commercial

- Prevents widespread cracking

- Better long-term slab performance

02 - Bridges & Highways

- Traffic creates constant high-cycle stress

- GFRP strength remains stable → safer surfaces

03 - Marine & Coastal Decks

- Salt attacks steel → strength loss

- GFRP = no corrosion, no strength reduction

04 - Industrial Facilities

- High tensile performance supports heavy machinery

- Strength durability = safer industrial operations

05 - Wastewater Treatment Plants

- Slabs exposed to wet conditions still maintain strength

- Reduced risk of chemical-induced cracking

06 - Healthcare & Labs

- Strong reinforcement maintains floor vibration control

- Important for MRI and operating room stability

07 - LEED & Sustainable Buildings

- Longer structural life → lower carbon footprint

- Stronger slabs reduce demolition and waste

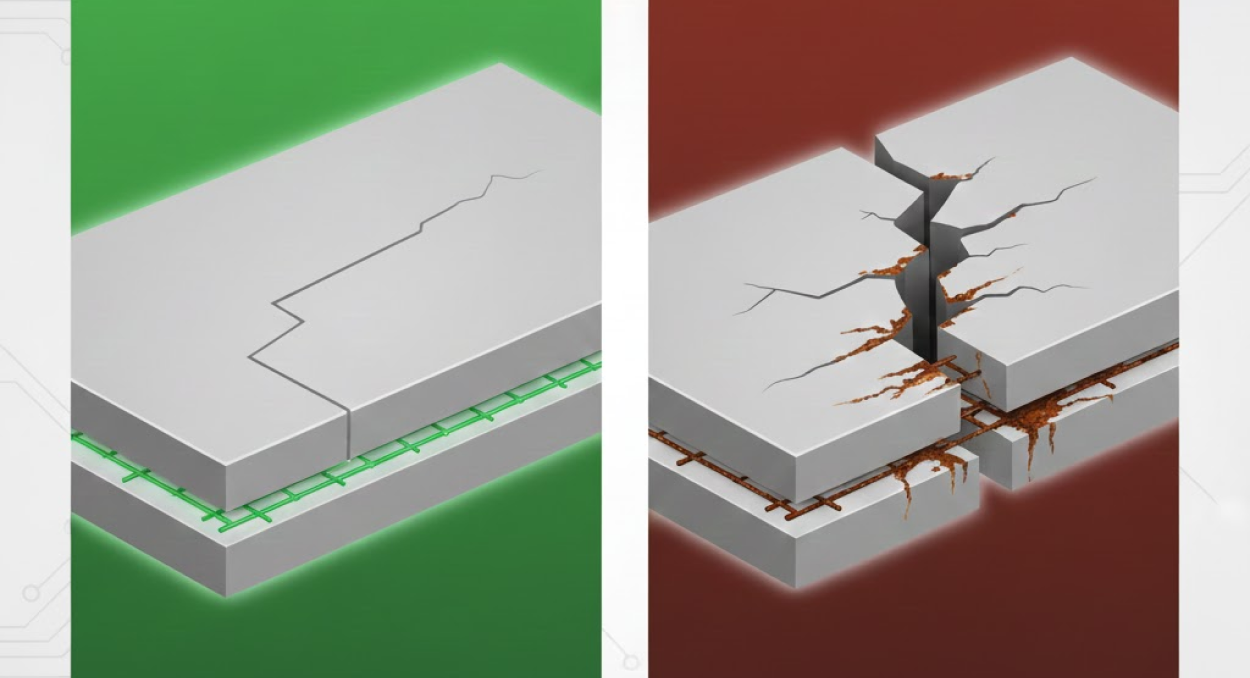

Real Case Example — Parking Garage

GFRP Mesh structure:

- Cracks stay tight

- Strength remains constant

- No expensive resurfacing

Steel Mesh structure:

- Cracks widen over time

- Water intrusion accelerates steel corrosion

- Structural repairs become frequent and expensive

Strength Retention Over 100-Year Design Life

Year

GFRP Strength

Steel Strength

100

High

Critical Failure Risk

Conclusion

Strength is not just about day-one performance. It’s about keeping structures strong for decades

GFRP Mesh delivers:

- High tensile strength

- Reliable bond for crack control

- No strength loss over time

- Optimal performance under heavy and dynamic loads

Zero corrosion isn’t a luxury — It's the new standard for modern construction. — visit: www.gogbars.com