Strength That Outperforms Steel: Why GFRP Rebar is the Smarter Choice

The high-tensile advantage that makes concrete structures safer and longer-lasting

Strength is the most critical requirement for any reinforced concrete structure. If the reinforcement fails, the concrete fails. For over a century, steel has been used because it is strong and readily available. But there is a major weakness in steel that cannot be ignored:

Steel loses strength over time due to corrosion

As corrosion progresses, steel weakens, cracks concrete, and threatens long-term safety.

GFRP Rebar (Glass Fiber Reinforced Polymer) is designed for modern infrastructure where high tensile performance must last 100+ years — with zero loss in strength.

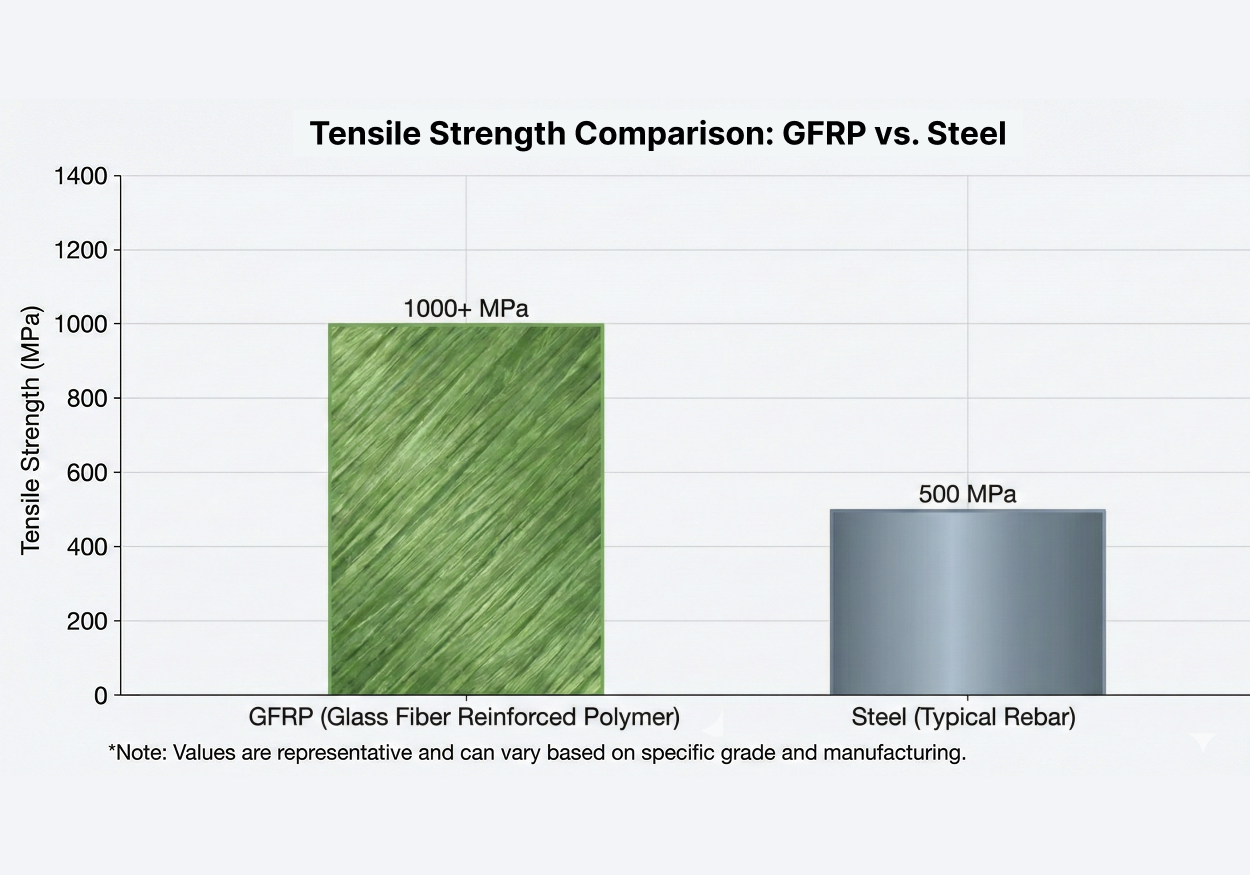

GFRP vs Steel: Tensile Strength Comparison

Steel offers tensile strength of ~60 ksi.

GFRP performance ranges from 100–180 ksi depending on bar size and manufacturer.

That’s up to 2–3X stronger than steel in tension.

Property

GFRP Rebar

Steel Rebar

Tensile Strength

100–180 ksi

~60 ksi

Strength Over Time

Maintains strength for 100+ years

Reduces due to corrosion

Rust Impact

None

Major structural risk

Strength That Never Weakens

Steel rebar starts strong but rapidly weakens as rust develops:

- Corrosion reduces steel cross-section

- Rust expansion causes concrete cracking

- Structural strength drops drastically

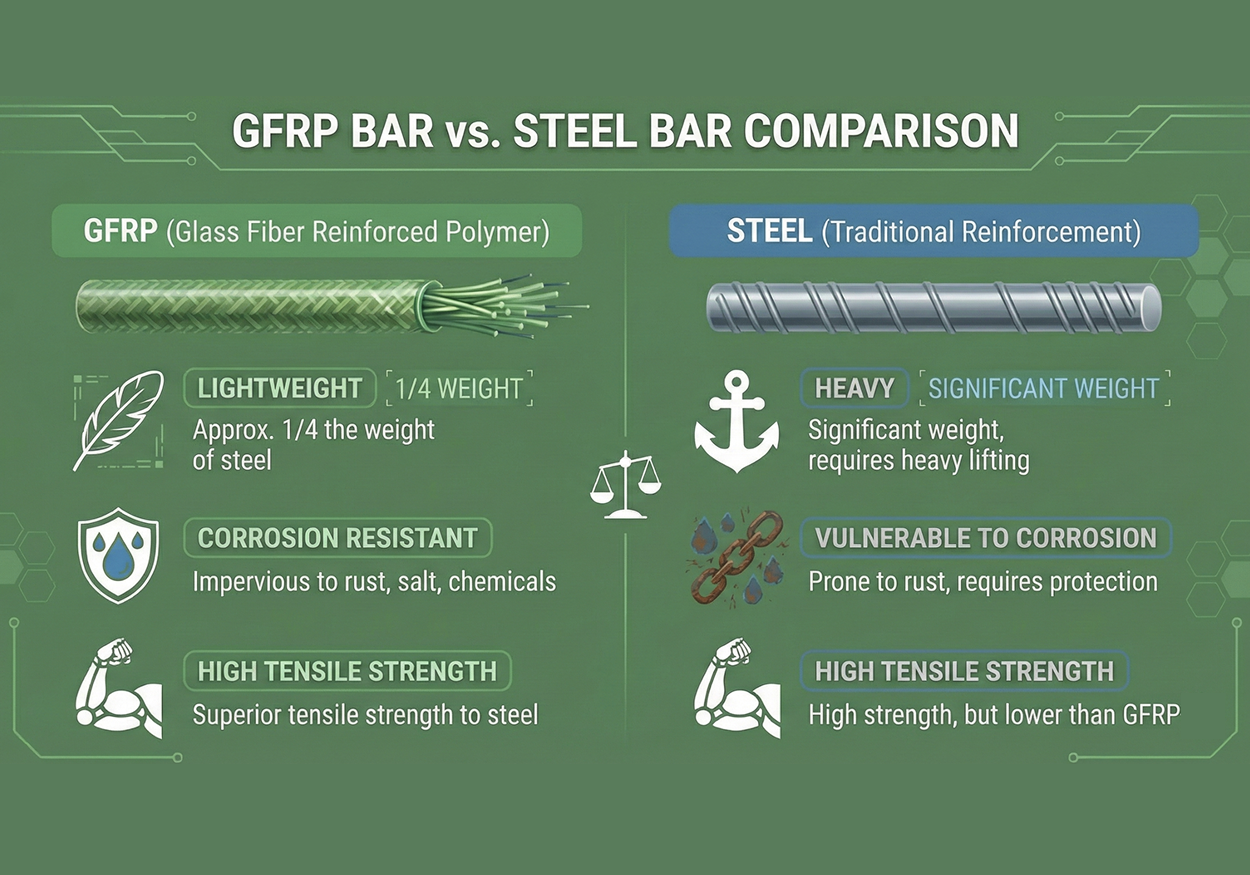

GFRP does not corrode, meaning:

- No strength reduction

- No expansion cracking

- No hidden structural deterioration

Concrete remains strong for decades with consistent load performance.

Strength-to-Weight Ratio: Big Performance, Small Weight

GFRP is:

- ~4X lighter than steel

- Higher load resistance for the same diameter

That means:

- Easier transportation

- Faster installation

- Safer handling

- Lower labor cost

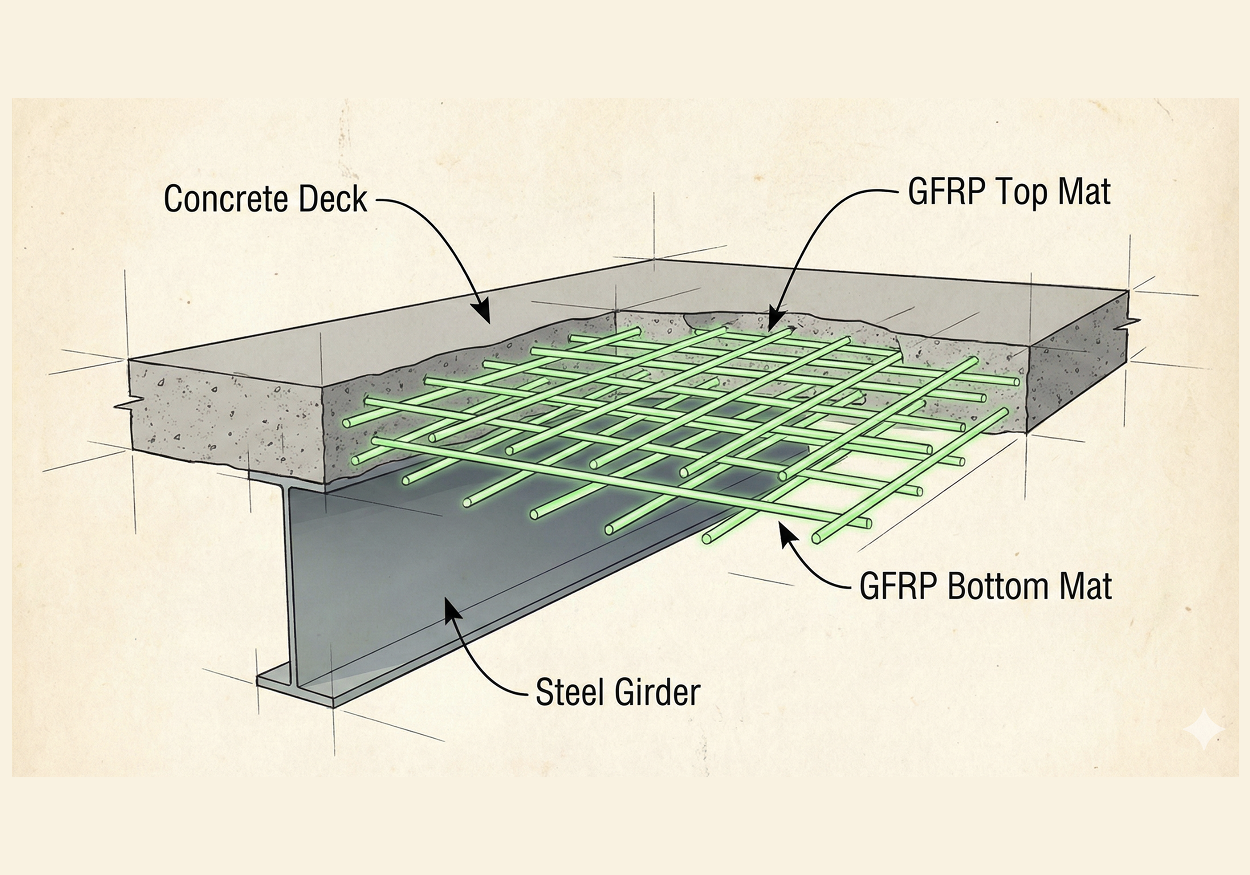

Superior Bond Strength with Concrete

GFRP bars are manufactured with sand-coated or ribbed surfaces to enhance bonding.

Advantages:

- Excellent adhesion to concrete

- Prevents slip under tension

- Reduced crack propagation

Strong tensile + strong bonding = higher structure reliability

GFRP Strength in Real Project Applications

Here’s how high strength improves performance in each major sector:

01 - Residential & Commercial

- Lightweight bars improve handling at urban job sites

- Strong tension control in slabs and foundations

- Reduces long-term cracking in basements and podium decks

02 - Bridges & Highways

- Heavy traffic + vibration requires strong tensile reinforcement

- Even stronger performance when exposed to temperature variation

- Zero strength decay → safer bridges for longer service life

03 - Marine & Coastal Structures

- Extreme durability under wave forces

- Stays strong even with constant chloride exposure

- Maintains tensile resistance even in submerged conditions

04 - Industrial & Chemical Facilities

- Supports heavy equipment loads

- No strength loss from chemical fumes and spills

- Reliable for tanks, floors, and high-stress areas

05 - Wastewater Treatment Plants

- Reacts well to constant pressure from containments

- No weakening from chemical exposure

06 - Healthcare & Labs

- High load demands in specialized medical spaces

- Vibration-sensitive environments prioritize structural stability

07 - LEED & Sustainable Buildings

- Strong long-life structures reduce repair waste

- Supports design goals for 100-year buildings

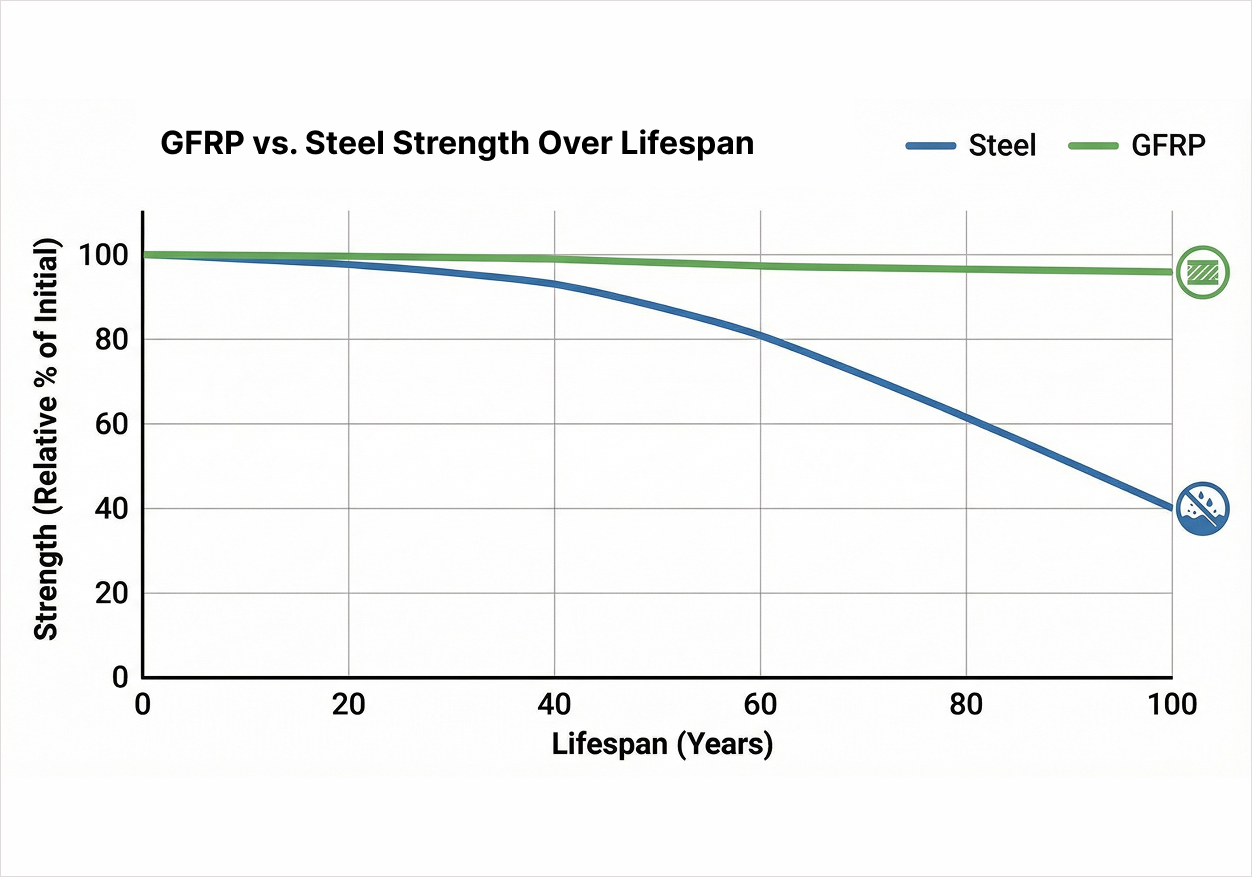

Lifecycle Strength Advantage

Steel structure strength curve drops over time due to rust: Strong → Weakened → Repairs → Failure

GFRP strength curve stays flat and stable for 100+ years.

Feature

GFRP Rebar

Steel Rebar

Tensile performance in year 1

Very high

High

After 20 years

High

Reduced

After 50 years

High

Major loss

After 100 years

High

Severe loss

Conclusion

Strength is not just about initial performance — it’s about retaining that strength for the entire life of the structure.

GFRP Rebar offers:>

- 2–3X tensile strength vs steel

- Strength that never degrades

- High bond performance

- Best strength-to-weight ratio in reinforcement

- Long-term structural reliability

Zero corrosion isn’t a luxury — It's the new standard for modern construction. — visit: www.gogbars.com