Stronger Bond = Stronger Concrete: The GFRP Mesh Advantage

Superior crack control and slab durability through consistent bond strength

In reinforced concrete slabs and decks, strength alone isn’t enough. The real performance comes from how well the reinforcement bonds with the concrete.

Bond strength ensures:

- Load is transferred effectively

- Cracks remain tight and manageable

- Slabs stay strong and safe for decades

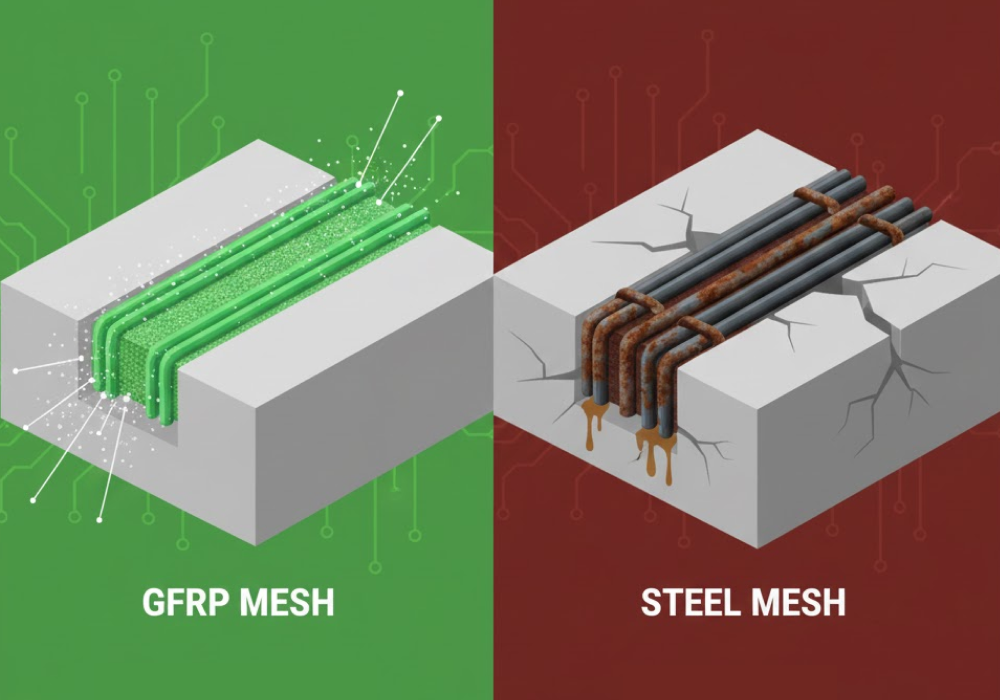

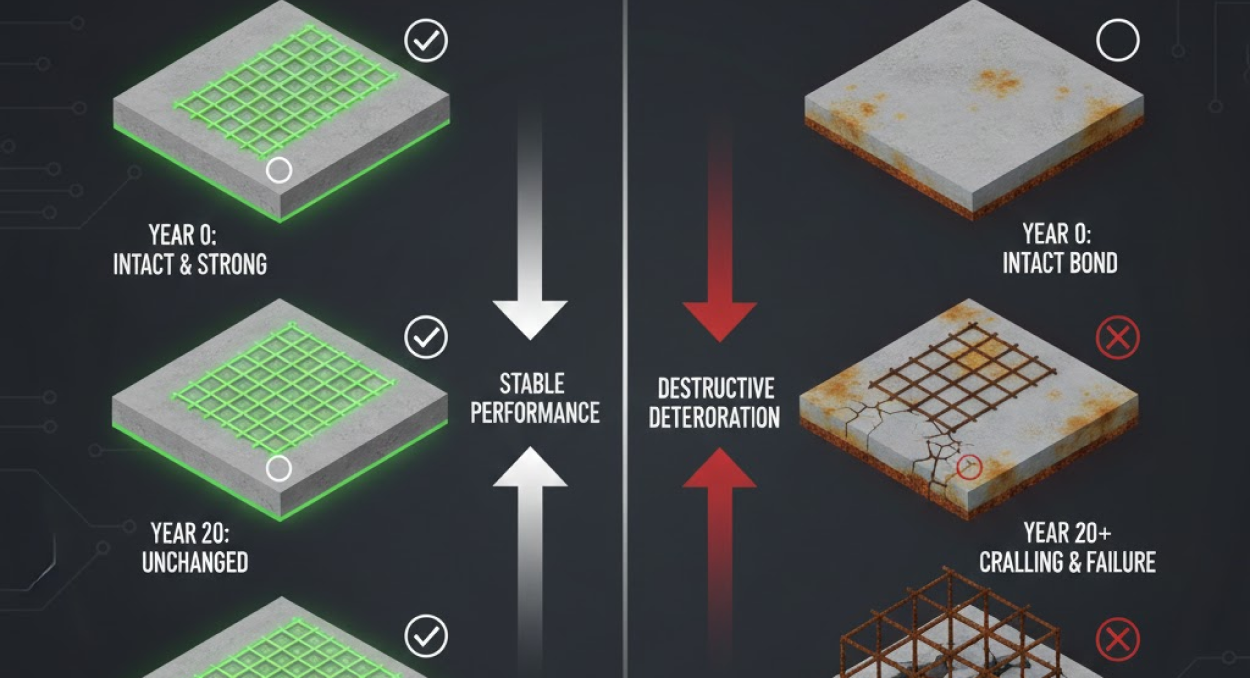

Steel mesh begins with good bond — but loses it quickly as corrosion sets in near the slab surface. GFRP Mesh (Glass Fiber Reinforced Polymer) maintains a high, stable bond throughout the structure’s entire life.

Why Bond Strength Matters in Concrete Slabs

Mesh reinforcement is placed near surface, the area most exposed to:

- Moisture

- Salts

- Abrasion

- Environmental weather cycles

When steel corrodes:

- Bond breaks

- Cracks widen

- Concrete spalls and delaminates

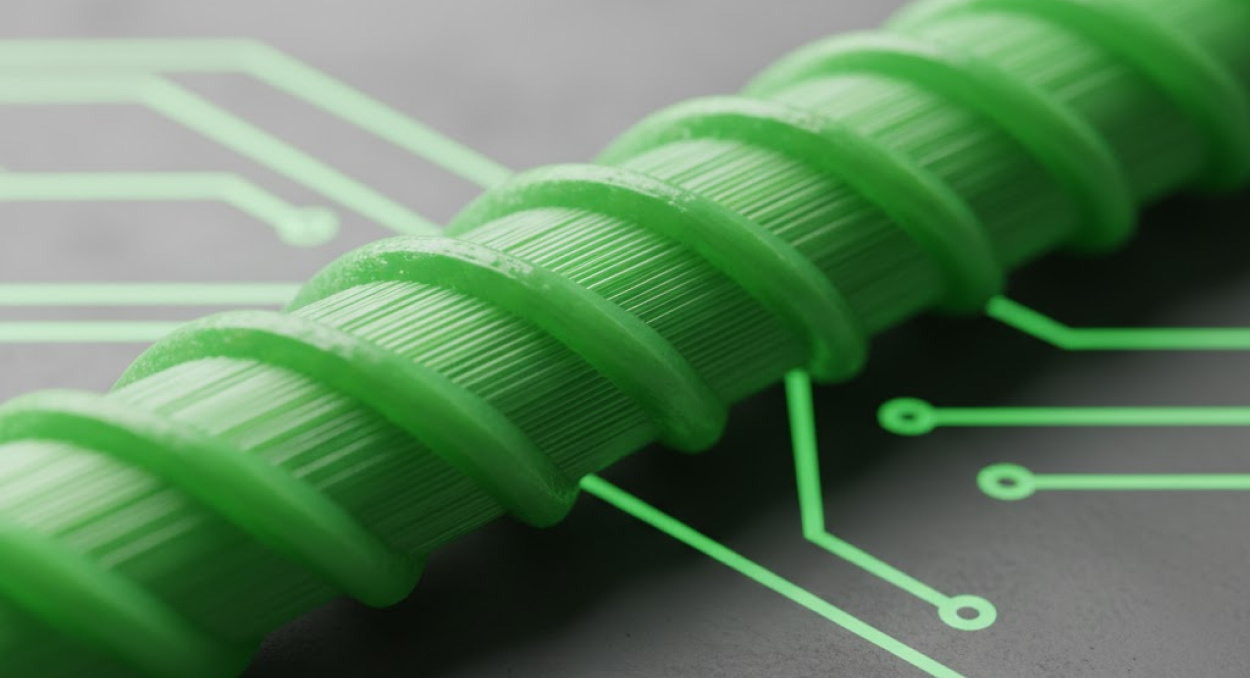

How GFRP Mesh Maintains Strong Bond Strength

GFRP is engineered to retain bond indefinitely:

- Textured, sand-coated surface for enhanced grip

- No rust → no weakening of surrounding concrete

- Stable anchorage during load and vibration cycles

- Maintains crack control for 75–100+ years

Bond Performance Comparison

Feature

GFRP Mesh

Steel Mesh

Initial Bond Strength

Excellent

Good

Exposure to Moisture

No impact

Rapid decline

Crack Control Over Time

Strong

Poor

Risk of Delamination

Very low

High

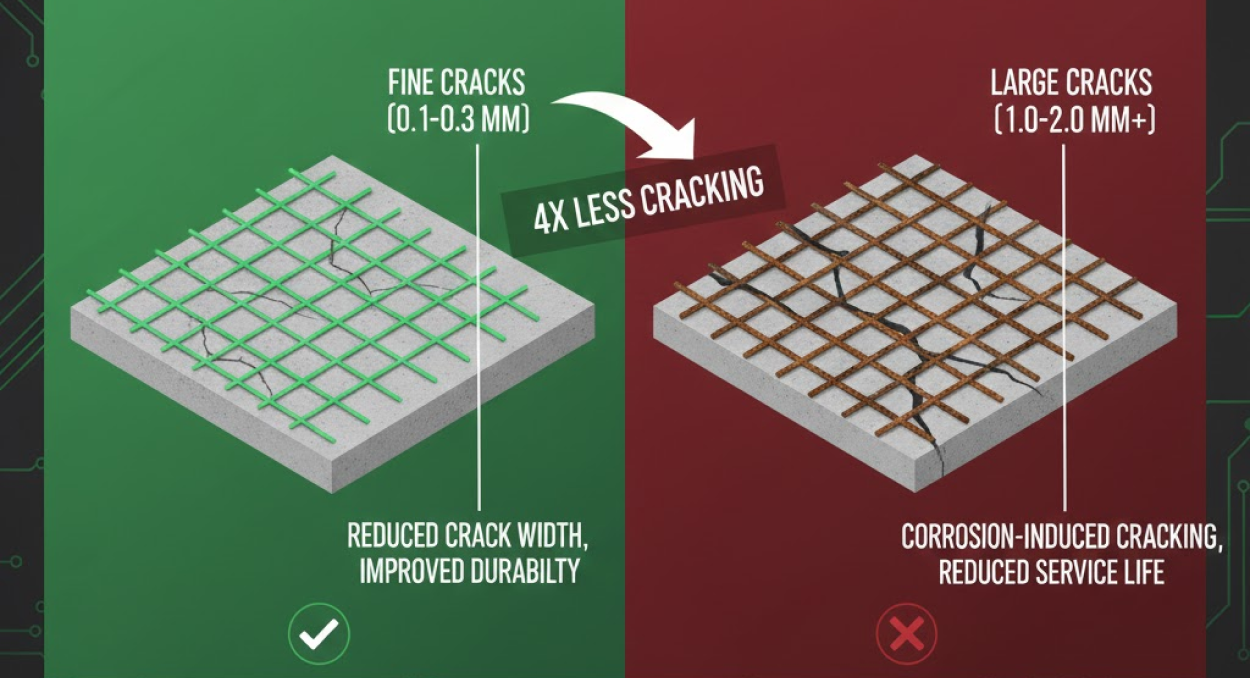

Crack Control = Longevity & Safety

GFRP Mesh keeps cracks:

- Tighter

- Less visible

- Less likely to propagate

GNarrow cracks prevent:

- Water intrusion

- Slab delamination

- Structural stress concentration

Application-Based Bond Strength Benefits

1 - Residential & Commercial Slabs

- Superior bond controls shrinkage cracks

- Floors stay smooth and safe long-term

2 - Parking Structures & Podiums

- Heavy traffic creates dynamic loads

- Strong bond prevents deck deterioration

3 - Marine & Coastal Boardwalks

- Chloride exposure destroys steel bond

- GFRP stays fully bonded in salt environments

4 - Industrial Flooring

- Vibration + machinery loads test anchorage

- GFRP Mesh keeps slabs structurally active

5 - Wastewater Treatment Plants

- Water + chemicals = steel bond failure

- GFRP bond stability = watertight performance

6 - Healthcare & Laboratories

- Better bond = better vibration absorption

- Critical in surgical and imaging rooms

7 - LEED & Sustainable Structures

- Longer bond stability = lower maintenance

- Reduced demolition = reduced waste

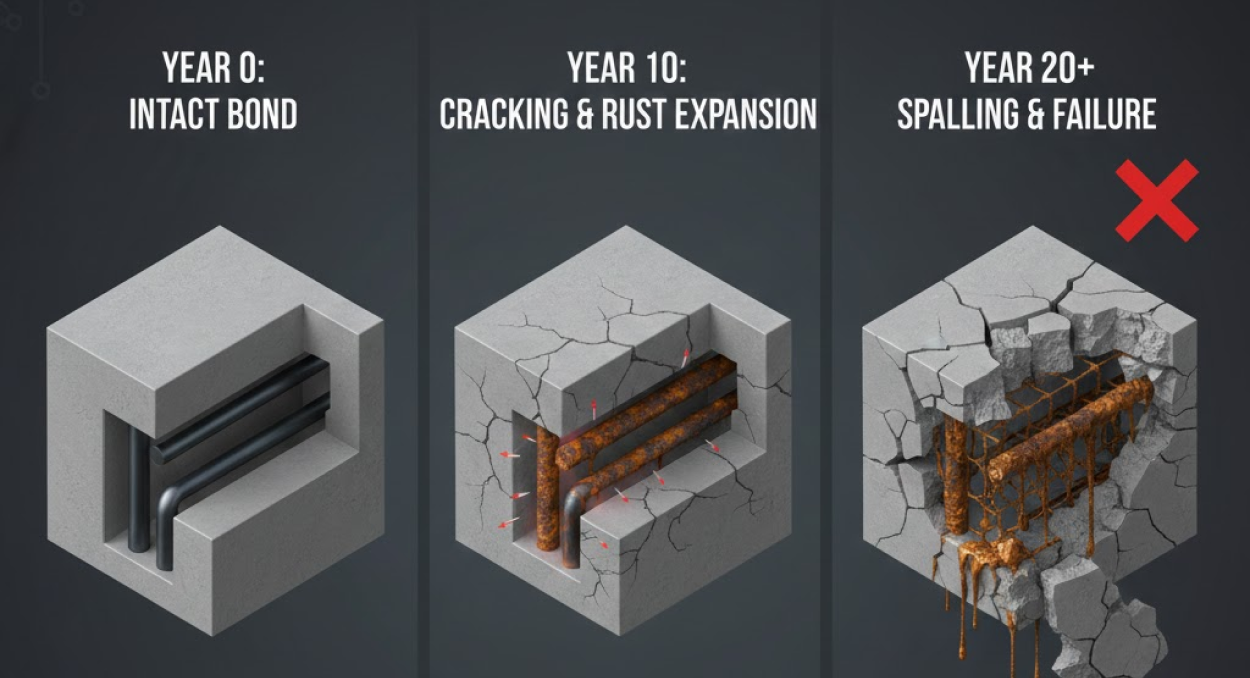

Real Case Example — Parking Deck Bond Failure

GFRP Mesh Outcome:

- No corrosion

- Strong bond remains

- No delamination or cracking

- Structure stays operational & safe

Steel Mesh Outcome:

- Corrosion → bond breaks

- Surface cracks widen

- Water leakage → slab deterioration

- Costly resurfacing every 7–10 years

Bond Strength ROI Table

Cost Factor

GFRP Mesh

Steel Mesh

Crack Repair

None

Frequent

Surface Delamination Risk

Minimal

High

Service Life

Very Long

Moderate

Operational Shutdowns

None

Costly

Safety & Reliability Benefits

A strong bond ensures:

- No sudden slab failure

- No hidden deterioration

- No weakening under fatigue loads

- No risk from water infiltration

ROI Table — Total Labor Savings

Conclusion

Bond strength is the key to reinforced concrete performance. If bond fails, the slab fails.

GFRP Mesh delivers:

- Superior initial bonding

- No corrosion-induced degradation

- Strong crack control

- Long-term slab durability

- Lower maintenance cost

Zero corrosion isn’t a luxury — It's the new standard for modern construction. — visit: www.gogbars.com