Build Green With GFRP Mesh: The Sustainable Reinforcement Choice

Durability that reduces waste, carbon, and lifetime impact

Sustainability is now a core requirement in construction. Architects, contractors, and developers must not only build strong — but also build responsibly.

Traditional steel mesh creates sustainability challenges:

- Corrosion leads to constant resurfacing

- Repairs cause landfill waste

- Equipment-based maintenance increases carbon emissions

GFRP Mesh (Glass Fiber Reinforced Polymer) eliminates corrosion

- Eliminating waste and maintenance cycles

- Making it a future-proof and eco-friendly reinforcement solution.

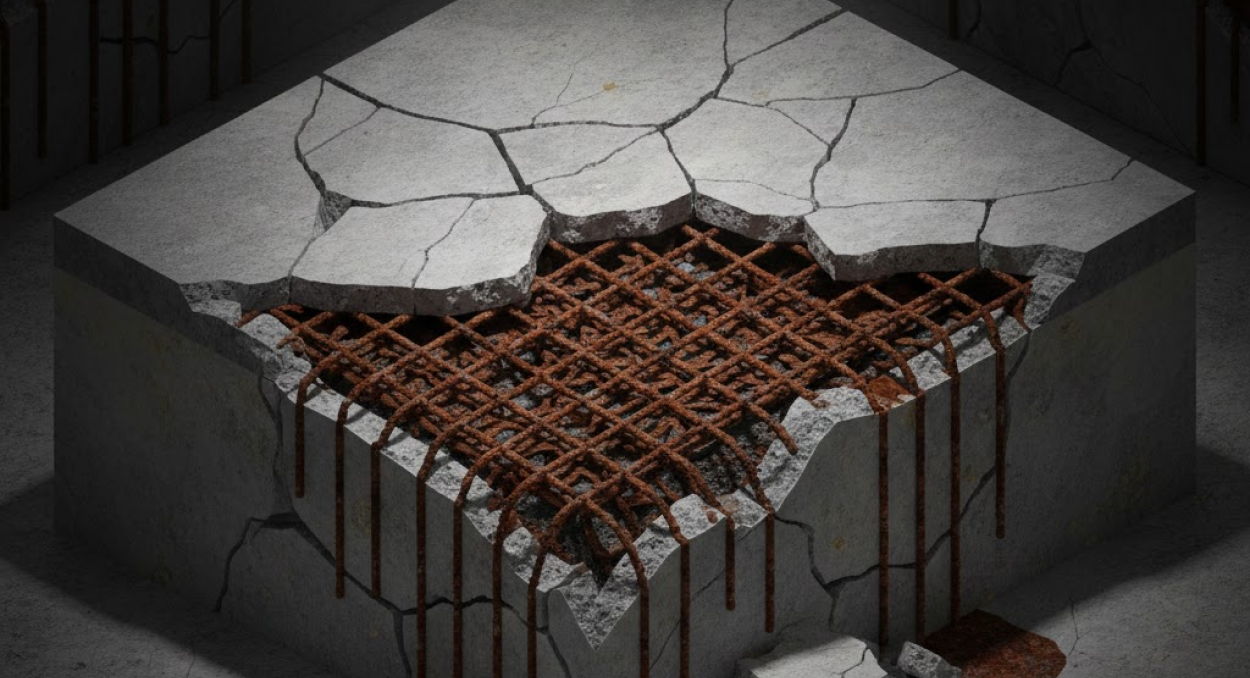

The Sustainability Problem With Steel Mesh

Steel mesh is placed near the concrete surface the most vulnerable location to moisture and chlorides

Corrosion effects:

- Rust expansion → slab delamination

- Surface cracking → waterproofing failure

- Costly resurfacing every 5–10 years

- Concrete ending up in landfills

- CO₂ emissions from repair trucks and machinery

How GFRP Mesh Enhances Sustainability

GFRP Mesh is engineered to solve the sustainability issues steel creates:

- Zero corrosion → no slab failure from rust

- No resurfacing waste

- Lifespan of 75–100+ years

- Lightweight → reduces transport emissions

- No coatings = no VOCs or chemical toxins

- Cleaner construction sites

Lifecycle Carbon & Waste Impact: GFRP vs Steel

Over its lifetime, steel mesh demands:

- Replacements

- Resurfacing cycles

- Heavy machinery use

- Extra concrete production

GFRP Mesh avoids all of that.

Sustainability Measure

GFRP Mesh

Steel Mesh

Repair Waste Generated

Zero

Very High

Transport Emissions

Low

High

Carbon Footprint Over 75+ Years

Very Low

Very High

Material Lifespan

Very Long

Short

Circular Economy Alignment

Strong

Poor

Longer Service Life = Lower Planetary Impact

When corrosion repairs are eliminated:

- No demolition debris

- No landfill pollution

- No production emissions from new steel

- No traffic closures and detours

- No repeated energy + labor waste

How GFRP Mesh Supports LEED & Green Projects

GFRP Mesh contributes to key environmental certifications and goals:

- Material Optimization Credits

- Reduced embodied carbon

- Zero corrosion repairs = lower operational carbon

- Supports long-life infrastructure mandates

Application-Based Sustainability Advantages

Sector

Sustainability Benefit

Residential & Commercial

Stops demolition waste from floor repairs

Parking Decks

Avoids resurfacing CO₂ emissions

Marine & Coastal

Prevents corrosion debris harming water ecosystems

Industrial Floors

Reduces repair shutdown emissions

Wastewater Plants

Eliminates contamination leaks from cracking

Healthcare

Prevents waste and disruption in critical environments

LEED Buildings

Ensures performance for green certification

Real Case Example — Parking Garage Sustainability

GFRP Mesh Slab:

- No corrosion → no resurfacing

- Carbon and waste reduction across entire lifecycle

- Structure stays safe and clean for long life

Steel Mesh Slab:

- Major surface repairs every decade

- Concrete waste hauled to landfill

- Crane equipment + repairs = high fuel use

- Operational disruption = lost revenue

Circular Economy & Environmental Value

GFRP Mesh contributes to:

- Better resource efficiency

- Single-cycle reinforcement instead of multiple replacements

- Maximum structural lifespan

- Zero toxic residue in soil or water

Conclusion

Steel mesh forces repairs, waste, and emissions into every project. GFRP Mesh eliminates the problem before it starts.

Sustainability Benefits of GFRP Mesh:

- Zero corrosion

- Zero repair waste

- Zero landfill impact

- Low-carbon logistics

- Long-life reinforcement

- LEED-friendly performance

Zero corrosion isn’t a luxury — It's the new standard for modern construction. — visit: www.gogbars.com