Sustainable Reinforcement: How GFRP Rebar Reduces Carbon & Waste

Longer-lasting infrastructure with a lower environmental footprint

Construction is rapidly evolving to meet green and sustainable standards. Environmental regulations, LEED certifications, and long-term infrastructure goals require materials that do more than perform well — they must also reduce waste, emissions, and lifecycle impact.

Steel rebar has long been used for reinforcement, but its biggest weakness — corrosion — leads to premature demolition, heavy waste, and repeated repairs, driving up carbon footprint.

GFRP Rebar & Mesh (Glass Fiber Reinforced Polymer) provide a modern reinforcement option with:

- Zero corrosion

- Longer service life

- Reduced CO₂ emissions

- Minimum maintenance and waste

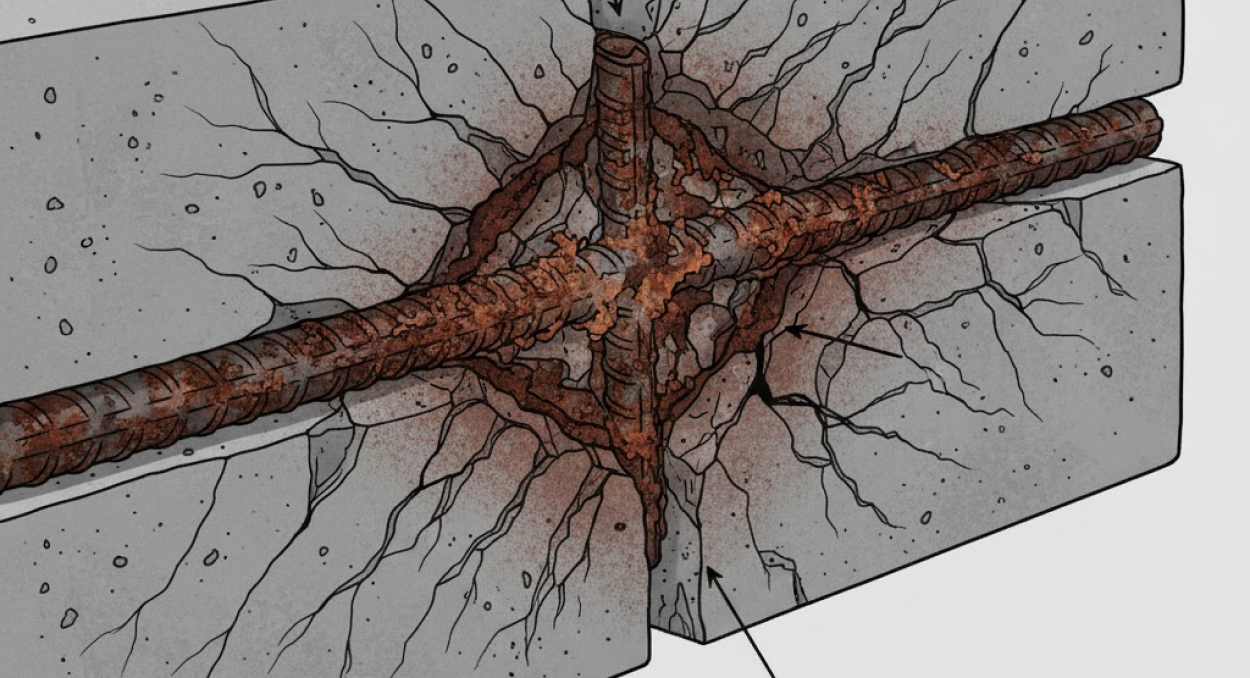

The Environmental Cost of Steel Corrosion

When steel rusts, concrete cracks. This causes:

- Demolition of large concrete sections

- Frequent patching and repairs

- Traffic detours and operational shutdowns

- Higher landfill waste

- Increased carbon emissions from new construction

Globally, corrosion in reinforced concrete is responsible for billions of dollars in structural repairs each year — and a significant amount of avoidable CO₂ emissions.

Why GFRP is a Greener Alternative

GFRP is engineered for a 100+ year service life with no deterioration, which means:

- No corrosion repairs

- No coating chemicals needed

- Less concrete waste sent to landfills

- Fewer reconstruction cycles

- Lower transportation emissions due to lightweight nature

- No heavy equipment required for installation

GFRP in LEED & Green Building Certifications

GFRP helps projects achieve sustainability and environmental performance goals, including:

- LEED Material Optimization Credits

- Reduced lifetime environmental impact

- Longer durability = lower replacement footprint

- Lower energy and emissions from transportation

- Improved operational continuity (no shutdowns)

Lifecycle Comparison — Carbon & Waste

Sustainability Factor

GFRP Rebar

Steel Rebar

Repair Waste

Zero

Very high

Service Life

75–100+ years

20–40 year

Carbon Footprint Over Life

Very low

High

Need for Replacement

One cycle

Multiple cycles

Hazardous Coatings

None

Often require

Application-Based Sustainability Benefits

How sustainable reinforcement improves different industries.

1- Residential & Commercial

- No major mid-life concrete repair waste

- Lower lifecycle cost for owners

- Better waterproofing — fewer damage claims

2- Bridges & Highways

- No rust means no traffic disruption for concrete repairs

- Less carbon from heavy machinery and rework cycles

- DOTs can achieve 100-year bridges

3- Marine & Coastal

- Steel rapidly corrodes in saltwater

- GFRP prevents demolition and waste from failed concrete

- Protects coastal resources and ecosystems

4- Industrial & Chemical Facilities

- Prevents chemical contamination caused by steel corrosion

- Less material replacement in hazardous areas

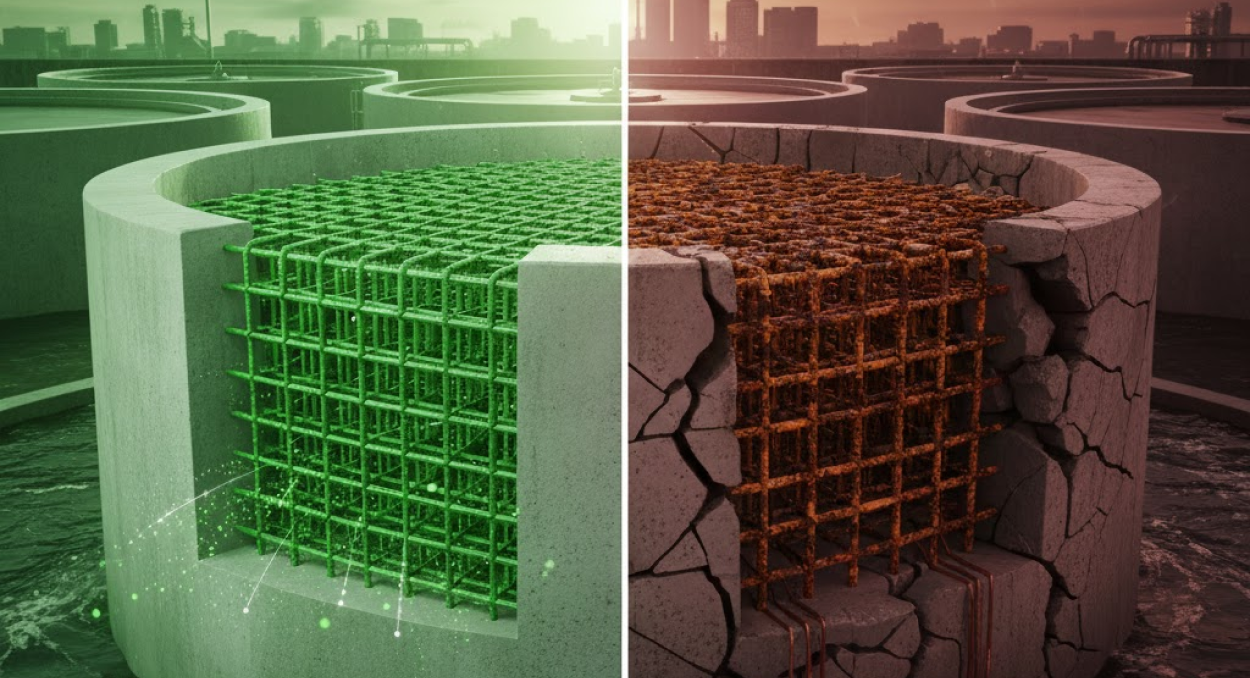

5- Wastewater Treatment

- Eliminates chemical corrosion-based failures

- Prevents leaks that could contaminate groundwate

6- Healthcare & Labs

- Fewer repairs → safe & clean operational continuity

- Supports hygiene and contamination control

7- LEED & Sustainable Projects

- Lightweight → fewer transport emissions

- Longer design life → less construction waste

- Perfect alignment with low-carbon infrastructure goals

Real Example: Marine Retaining Wall

With steel rebar:

- Severe corrosion in 15–20 years

- Full demolition required

- Tons of concrete waste dumped into landfill

- High CO₂ emissions from rebuild

With GFRP Rebar:

- No corrosion → no demolition

- Structure stays intact for 75–100+ years

- Zero waste from reinforcement failure

Sustainability ROI Table

Factor

GFRP Rebar

Steel Rebar

Waste Production

Lowest

High

Carbon Emissions

Low

High

Service Disruption Impact

None

Major

Material Replacement Cycles

1 cycle

2–3 cycles

Environmental Compliance

High

Low

Conclusion

True sustainability is not just about materials — It’s about eliminating failure and preventing waste.

GFRP Reinforcement delivers:

- Zero corrosion

- Longer service life

- Lower carbon footprint

- Reduced landfill waste

- LEED-friendly performance

- Better outcomes for future generations

Zero corrosion isn’t a luxury — It's the new standard for modern construction. — visit: www.gogbars.com