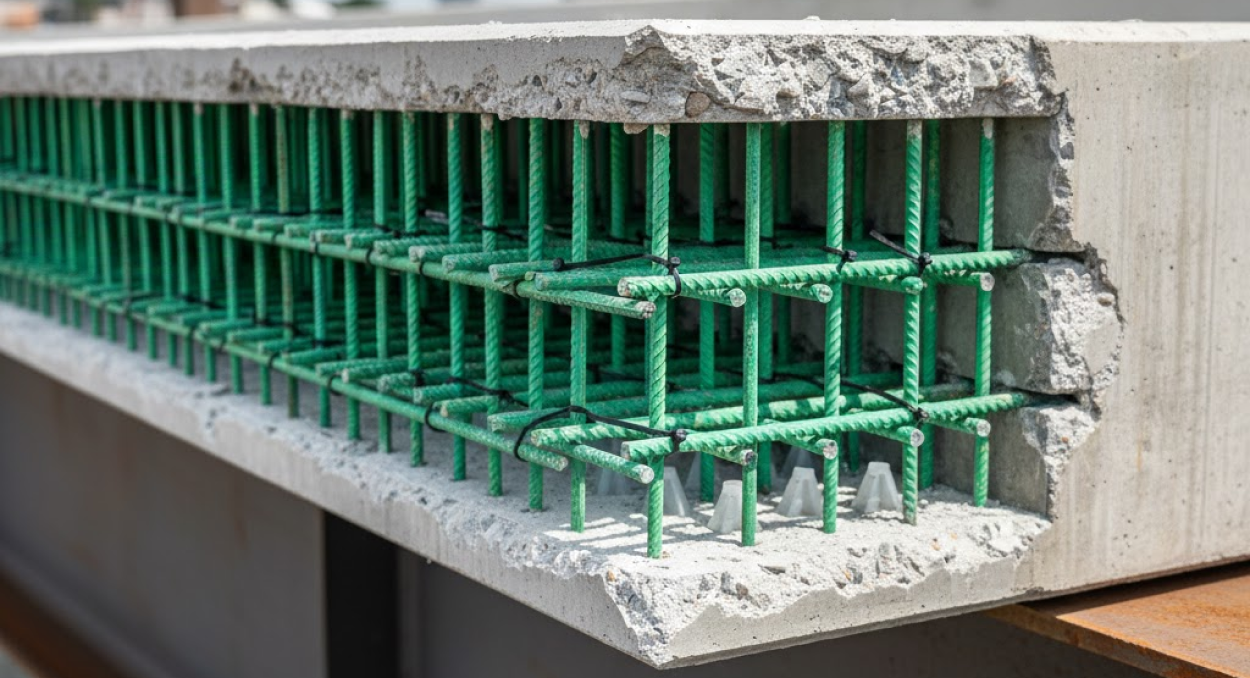

Stronger Together: How GFRP Rebar Achieves Excellent Bond Strength with Concrete

Better crack control and long-term load performance

Concrete is strong in compression — but weak in tension. That’s why reinforcement exists: to carry tensile forces and prevent cracks from widening.

For the reinforcement to do its job effectively, it must bond strongly with the surrounding concrete. Poor bond strength leads to:

- Slip between reinforcement and concrete

- Wider and faster crack development

- Reduced structural performance and safety

GFRP Rebar and GFRP Mesh are engineered to deliver superior bond strength, ensuring concrete structures remain durable — for their entire lifespan.

Why Bond Strength Matters?

Bond strength is what ensures:

- Load transfer between concrete and reinforcement

- Cracks stay small and manageable

- Structural performance remains reliable

- No sudden failures from reinforcement slip

Steel has good initial bond — but its major weakness:

Corrosion reduces steel’s bond strength over time

How GFRP Rebar Maintains High Bond Strength

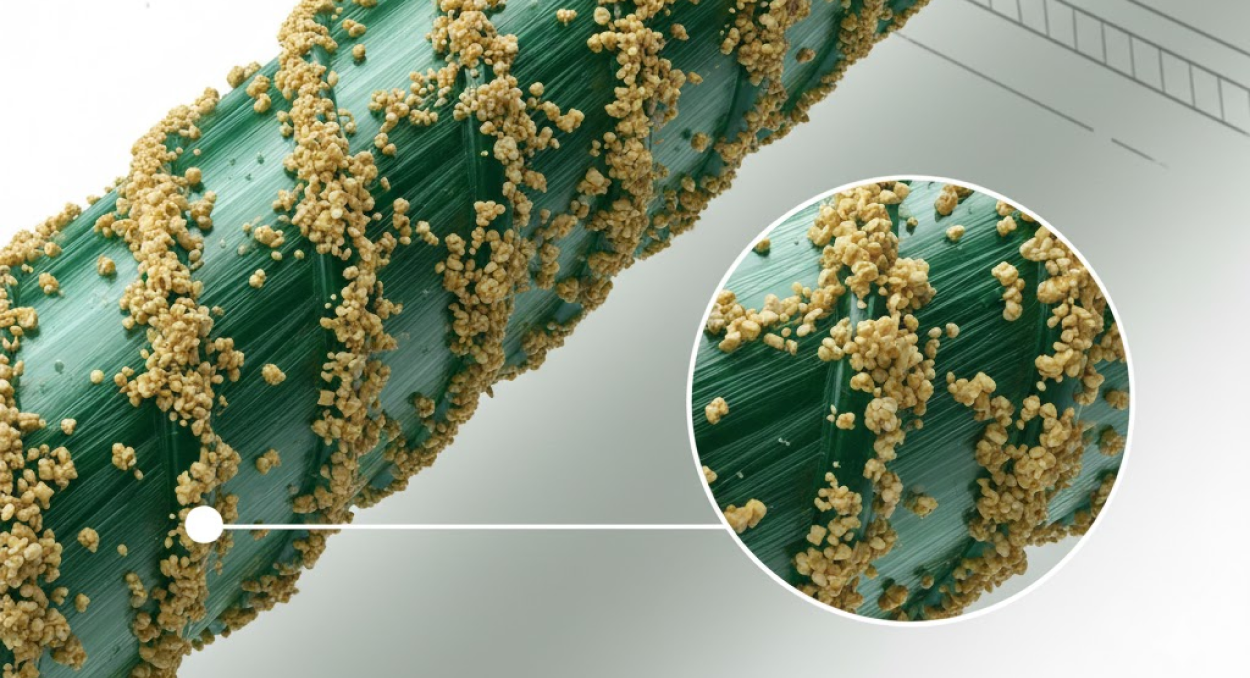

GFRP reinforcement is designed specifically for excellent bonding:

- Sand-coated surface provides friction grip

- Ridges and helical texture enhance mechanical interlock

- Chemical inertness prevents surface deterioration

Steel vs GFRP — Bond Performance Comparison

Feature

GFRP Rebar

Steel Rebar

Initial Bond

Excellent

Good

Long-Term Bond

Remains strong — no corrosion

Weakens — corrosion breaks concrete bond

Crack Control

Constant crack resistance

Declines as steel rusts

High-Chloride Areas

No performance loss

Rapid deterioration

Bond Strength Importance in Applications

Below: How strong bond improves performance across industries.

1- Residential & Commercial Buildings

- Reduced slab cracks → fewer waterproofing issues

- Better long-term performance in basements & podium decks

Example:

High-rise podium slabs using GFRP avoid crack repair costs in parking areas.

2- Bridges & Highways

- Traffic vibration constantly stresses reinforcement

- Strong bond prevents acceleration of cracks

- Better durability in bridge decks and barriers

Example:

High-rise podium slabs using GFRP avoid crack repair costs in parking areas.

3- Marine & Coastal Structures

- Saltwater accelerates steel bond failure

- GFRP stays bonded under harsh chloride exposure

Example:

Coastal piers using GFRP avoid severe cracking that leads to expensive concrete spalling.

4- Industrial & Chemical Facilities

- Dynamic machinery loads demand high load transfer efficiency

- GFRP bonding remains unaffected by chemical exposure

5- Wastewater Treatment Tanks

- Tanks must stay watertight

- Strong GFRP bond avoids crack leaks and contamination risks

6- Healthcare & Labs

- Crack prevention helps support clean, controlled environments

- Essential for hospitals and pharmaceutical facilities

7- LEED & Sustainable Projects

- Minimal cracking = longer life = fewer repairs = lower carbon impact

- Essential for hospitals and pharmaceutical facilities

Real Case Example — Wastewater Tank

A treatment plant reinforced with steel:

- Rust appears in a few years

- Cracks widen → leaks develop

- Major repair needed

Same application with GFRP:

- Bond remains strong

- No crack expansion

- No shutdown for maintenance

Bond Strength ROI Benefits

Performance Factor

GFRP Rebar

Steel Rebar

Long-Term Bond

Maintains

Weakens

Crack Resistance

Consistent

Reduces

Repair Cost

Zero corrosion repairs

High

Service Life

Longer

Shorter

Conclusion

Bond strength is what ensures concrete and reinforcement behave as one. If the bond fails — the structure fails.

GFRP Rebar & Mesh provide:

- Superior bond performance

- Consistent crack control

- No corrosion damage

- Reinforcement reliability over 100+ years

Zero corrosion isn’t a luxury — It's the new standard for modern construction. — visit: www.gogbars.com